19/10/2023 – 1st ITSCDC@University of Applied Science, Mönchengladbach

Promoting technology transfer

The foundation of any digitized processes, production-related and from cradle-to-grave for finished goods, lays in the collection and targeted processing of valuable data: As well yet not only in that regard the Textile and Apparel faculty of University of Applied Science with the International Textile Supply Chain Digitalization Conference (ITSCDC), very first of its kind, arranged a unique setting at their Mönchengladbach/Germany campus – back in September.

Over three enlightening “Summer School” days high-level keynotes by academic and industrial experts, research and industry presentation sessions were offered - plus workshops to discuss the academic, educational, and industrial challenges, needs and major achievements focusing on textile scenarios.

Transformation towards a fully integrated digital way of working is possible. Taking advantage of this fact is simply without alternative for any format of future-oriented business models. In view of the almost limitless possibilities with regard to design and product development, engineering as a whole, manufacturing, merchandising & marketing, it is not so much the feasibility down to the last detail that causes concern: Much more it is knowledge transfer of what technology has to offer right here and now, results of dedicated R & D at the fingertips of the “makers”, those of ready goods as well as tech-suppliers.

Some exemplary insights – of plenty

At the end of the day, it's all about the readiness and the opportunities for timely adoption. The University’s new event format comes into play as well to overcome that transfer gap. Here comes for a few at-a-glance take aways.

To unlock the success for 3D fashion design as pre-requisite for fully digital eco-systems in textile and apparel education appears to a key driver towards readiness for digital. Indeed along with an all collaborative approach This is precisely where the Digital Fashion Project, under the coordination of the Belgian Hogeschool Gent, comes in with its project to develop a Knowledge Library and Training Platform.

Transferring physically known fabrics in the virtual world

The EU-funded project with its partners from key European educational institutes on board focuses on the development of a training method for fashion design based on a 3D garment visualization platform. Addressing pre-dominantly higher education students and young professionals in the area of virtual prototyping, and virtual garment development the platform doubtlessly represents perfect tool to empower for broad market demands. The Library of Knowledge research results will offer practice-oriented benefit to also an industrial level with:

a fabric database ( physical + digital)

a styles/patterns database ( by now for 4 garments)

a 3D garment database – a 3D human database ( sizes and their variations)

The fabric digitization process

Coping with the challenge to implement AI

Ricardo Vega Ayora, Project Engineer at ITA (Institute for Textile Technology at RWTH Aachen) introduced the Innovation and Learning Center at the ITSCDC Conference and with that The Model Factory of the Future. Accomplished along with key tech partners such as Brother, Ekko; PTC, Optimitive, Oniq, Syntactix and also consultancy firm McKinsey the factory is sited at the city right in the border triangle of Germany, the Netherlands and Belgium: With that it represents a central location to display real-life demonstrations, learning environment as well as a test base for piloting and scaling-up new digital solutions.

As proof of the pudding for feasibility Avora presented the exemplary case study of a smart woven elastic wrist band for personalized login, carrying a customized print – produced in batch-size one over the complete chain from warping, weaving, coating and heat setting, printing and cutting, assembly – up to final quality control for full functionality.

Survey activities accompanying the initiative also help to identify and verify the obstacles for AI implementation:

Lack of internal knowledge: Companies report that they have limited knowledge of the topic, AI skills, expertise, or programming capabilities in their staff.

Another barrier for the adoption of AI in the industry are the high costs of the development platforms and the development itself.

High project complexity: The tasks that companies seek to automate through AI such as augmentation of workforce are often too complicated for existing off-the-shelf solutions.

“We offer management workshops for managers and technicians across all industries who are responsible for operations”, stressed Avora. “Our aim is to support companies during their digital transformation to increase productivity and efficiency.”

Laying the foundation for Industry 4.0

… via a continuous forward-looking planning of opportunities through innovation: Right away into the industrial implementation of digital technologies for a whole range of inhouse-developed as well as third-party innovation Dr. Thomas Schmidt led the delegates of the 1. ITSCDC. The Director of Innovation & Creation at Huafeng, granted insights on the Chinese Textile Group’s strategy to move towards actual Industry 4.0, based on their non-linear business model in place - comparing it with the current linear business model of the sports footwear industry.

Along his exemplary use case for product development and production of sport shoes Dr. Schmidt provided a glimpse into 3D product development for sneakers plus the execution of the company’s additive application process for highest material efficiency: “Haptic 3-D additive coating technology is laying the foundation for our further development into Industry 4.0 business environments”, explained Thomas Schmidt.

Along Huafeng’s vision “to serving the globe with sustainable, innovative, top quality textile solutions”, the high-tech textile enterprise with its independent R&D activities utilizes alternative raw materials: Biomass and also waste stream as it becomes more available enables the lowering of the ecologic footprint - for themselves and thus their international brand customers in the sports goods segment.

Hohenstein: Hands-on support for successful 3D simulation

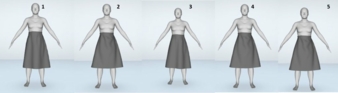

“To actually reduce the number of prototypes with the implementation of 3D technology, it is crucial to create reliable virtual prototypes, that are as close as possible to the final product”, emphasized Flora Zangue over her presentation on the development of production guide lines for 3D garment simulation by Hohenstein’s Digital Fitting Lab. Elaborated step-by-step descriptions for the processing of virtual garments aim to enable any 3D user to achieve consistent simulation’s results using the guideline – “independently from individual skill levels”. The premiere paper introduced at Mönchengladbach had been developed based on the application of Clo 3D software. Next steps for that latest service concept by Hohenstein Laboratories, globally established for the Oeko Tex certifications:

Validation of application through more users

Development of further production guidelines for various 3D software systems

Constant updates for all guidelines along 3D simulation system updates, new functions to simplify workflows

The Hohenstein Academy offers a variety of webinars and live demonstrations on the application of 3D software.