07/11/2023 – Jeanologia

Transforming denim design with “eDesigner”

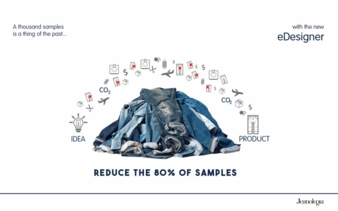

Jeanologia, a Spanish company specializing in the development of eco-efficient technologies, has launched an updated version of its “eDesigner” software, that revolutionizes denim design by promoting eco-friendly practices.

The software significantly reduces the need for physical samples, leading to an estimated 80% reduction, and ensures precise reproducibility in garment production. The latest version offers an improved user interface, enhanced hyperrealism, and integrates fabric digitization, and access to Jeanologia`s expertise, fostering a seamless collaboration between designers, wash developers, manufacturers, and brands for faster design validation and accelerated production and marketing. Here you can find a more detailed overview:

Editor for denim design

The new version of the “eDesigner” offers a more intuitive user interface, as well as special tools for denim design that enable a unique design experience. Worth highlighting is the trace tool, which uses artificial intelligence to generate hyper-realistic designs from a single image. It also features the possibility of working with digitized fabrics, thus enhancing hyperrealism with high-definition renders to ensure that the design seen on the screen is what will be obtained in production: “What you see is what you get”.

Access to Jeanologia`s know-how

“eDesigner” also provides designers with a valuable source of inspiration and expertise through its “Lightbrary”, which gives users access to an extensive gallery of laser designs, vintage designs, wash effects, textures, tear and fray gallery, as well as a discover section with trends and inspirational designs. Jeanologia makes its expertise available to designers who can use it to create things from scratch or build on previous designs as a starting point for new creations.

Digital wash

The new “eDesigner” takes digitization to the next level, enabling the digital creation of patterns and garments and in doing so, is said to reduce physical samples by 80%. This not only means significant savings in terms of resources, but also a substantial reduction in the carbon footprint generated by the transportation of samples. The user can create digital cufflinks, combining digital patterns (“eFit”) with digital fabrics (“eFabric”), and take part in a truly authentic experience, as he or she will be able to analyze the results of wash applications on the fabrics. All these innovations make it possible to shorten product development times by months, eliminating significant sample quantities and the now-unnecessary costs of shipping them around the world.

Partner for the digitization of the development process

“eDesigner” acts as a fluid and agile two-way communication channel that connects laser designers with wash developers and brands with manufacturers. In this way, it speeds up the production and marketing of collections. Once the design is finalized and the collection approved, the tool provides final digital files, which can be sent to production centers around the world to be converted into actual jean production. As Jeanologia`s Marketing Director, Carmen Silla, explains: “Thanks to this tool we`ll enable infinite iterations at zero cost and impact, while standardizing formats and communication. We`ll improve production processes by making them more efficient and accelerate time-to-market, since we go from design, to sample and approval in a very short time.”

As a result “eDesigner” is more than a software. It is said to be an eco-efficient digital transformation tool, destined to revolutionize the textile industry and contribute to its transformation into a more competitive, productive and sustainable industry.