13/09/2018 – Australia — auf Deutsch lesen

Fish leather as a business idea

The light blue corrugated halls of an industrial estate in Esperance, south-west Australia, are home to the country’s only maker of fish skin leather.

Not surprisingly, the enterprise has grown into a popular destination for tourists. After all, a product made of fish leather is something of an attraction and makes for an interesting souvenir.

Mermaid Leather processes the skins of giant sea bass, small shark species and snappers. The local fish factories supply the fish skins which would otherwise be thrown away.

The MacDermott brothers are proud of their business idea which started taking root at a BBQ fish party. Every year, the company processes around 10,000 fish skins – and rising. The fresh skins are sent down the road to the tannery directly after removal. This means they do not need to be preserved in salt, resulting in considerable cost-savings. The first task involves removing the scales by machine. The skins are then exposed to a seven-phase production process which takes around six weeks, after which the pungent odour of fish, all the bones and flesh have been completely eliminated.

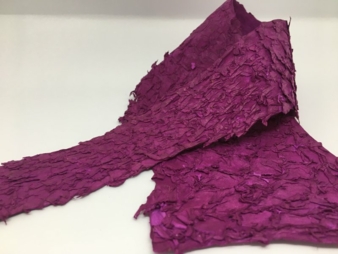

The finished leathers have a very natural appearance and come in a variety of earthy tones and interesting, exotic looks. The showroom, which doubles up as a sales room, is filled with a large selection of fascinating, high-quality handbags, purses and accessories. In comparison with conventional leather, shark’s leather has excellent tear strength and durability.

Andy MarcDermott explains that there are no bureaucratic hurdles – such as animal protection or veterinary regulations – to exporting products made from fish leather. The same applies to the conservation of species because none of the fish mentioned are subject to any legal requirements in the international CITES agreement.