15/08/2024 – Hermes Barometer on risk management along the supply chain — auf Deutsch lesen

Focus on Digitization and Collaboration

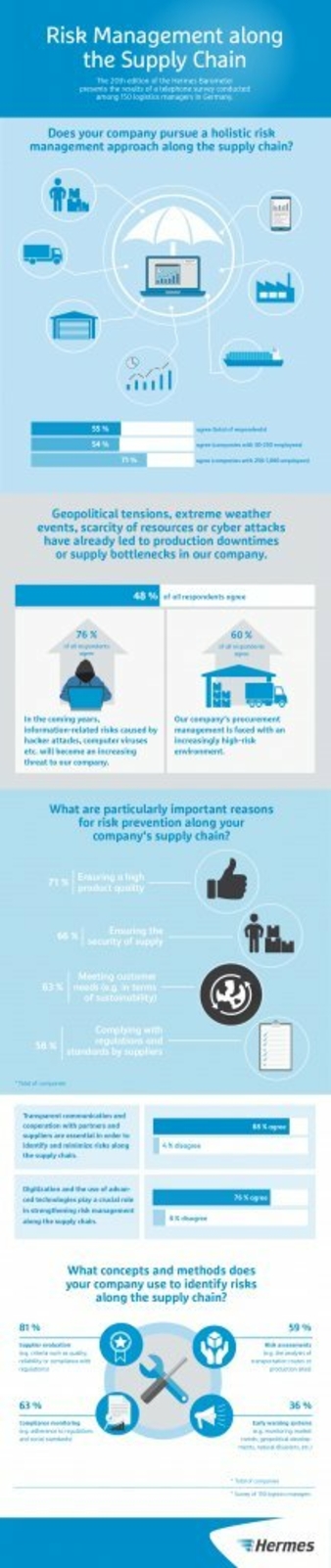

Digitization plays a key role in making supply chains more secure: This view is held by more than two thirds of a total of 150 logistics managers at German companies.

After all, the use of advanced technologies supports data collection and analysis – and therefore plays a key role in risk analysis and management. However, the survey for the 20th Hermes Barometer “Risk Management along the Supply Chain” also shows that while companies are aware of the importance of effective strategies against potential disruptions, only every other company considers their current risk management to be effective.

An increasing number of companies is pursuing a holistic risk management approach along their supply chain: more than one in two survey participants (55%) state that they have implemented a corresponding concept for the automated monitoring of all supply chain management processes. However, the figure is rising to 71% for larger companies with 250 to 1,000 employees. This increase of 16 percentage points compared to the results of the 2019 barometer (39%) is by no means coincidental: in light of increasing cyber attacks, resource scarcity and geopolitical tensions, respondents expect the threat situation to intensify significantly.

“With complex, global supply chains in particular, companies need to safeguard their business practices using holistic risk management: even a small disruption in the product cycle can have a direct impact on downstream parts of the supply chain,” Moritz Gborglah, Division Manager Operation at Hermes International, confirms the results.

Individual measures to minimize risks

To protect against risks, the companies surveyed have already integrated a number of solutions into their business processes. Eight out of ten logistics managers (81%) see supplier evaluation as a particularly important risk prevention measure: they already use the opportunity to check and evaluate criteria such as quality, reliability or compliance with regulations. Compliance monitoring and risk assessment are popular methods for identifying disruptions at an early stage and are used by 63% and 59% respectively to reduce failures, delivery bottlenecks or quality defects in the supply chain.

Product quality is a priority for companies

With their risk prevention approaches, the participants of the 20th Hermes Barometer survey are pursuing key strategic goals. Above all, ensuring a high product quality is seen as very important by 71% of respondents, underlining how crucial quality assurance is for competitiveness and customer satisfaction. In addition, the demand for security of supply and the fulfillment of customer needs drive companies to take security measures for their supply chain.

Last but not least, more than one in two respondents (58%) cite compliance with regulations and standards of their suppliers as a reason for their risk mitigation strategies. However, while the companies surveyed are pursuing ambitious goals, only every other survey participant actually considers their risk management to be effective.

Digitization and transparent collaboration for secure supply chains

According to the results of the 20th Hermes Barometer, two aspects in particular could help to promote a holistic risk management for the supply chain. The majority of the companies surveyed see digitization and the use of advanced technologies as a decisive factor in strengthening risk management within the supply chain. At 76%, more than two thirds of respondents agree that smart solutions and tools are important for identifying risks at an early stage and managing them proactively. In organizations with 250 to 1,000 employees, as many as 82% share this view. “The use of AI-supported forecasting models or IoT technologies allows us to analyze and interpret complex data patterns in the supply chain – such as information about suppliers, transport routes or stock levels – in real time. This leads to anomalies, delays or bottlenecks being detected more quickly,” explains Gborglah when categorizing the results.

According to supply chain managers, transparent communication and collaboration with partners and suppliers also contribute to an effective risk management: A convincing majority of 88% of all respondents emphasized the importance of these processes. An integrative communication strategy therefore not only optimizes risk identification, but also contributes to strengthening overall supply chain resilience by increasing the ability to react to unforeseen events. “Transparent communication goes beyond the simple exchange of information and leads to the development of proactive strategies that not only minimize risks, but also increase the agility of the supply chain,” explains Gborglah. “Those who intensify communication with other relevant supply chain players strengthen operational excellence, enable rapid adjustments to market changes and gain a strategic competitive advantage in the long term.”

About the survey

Participants: 150 logistics managers

Method: Telephone survey

Survey period: May 2024