03/07/2020 – Faster, more flexible and energy-saving

Weber Ultrasonics: Ultrasonic laminating

One of the largest European producers of nonwoven fabrics and their end products relies on ultrasonic welding with technology from Weber Ultrasonics.

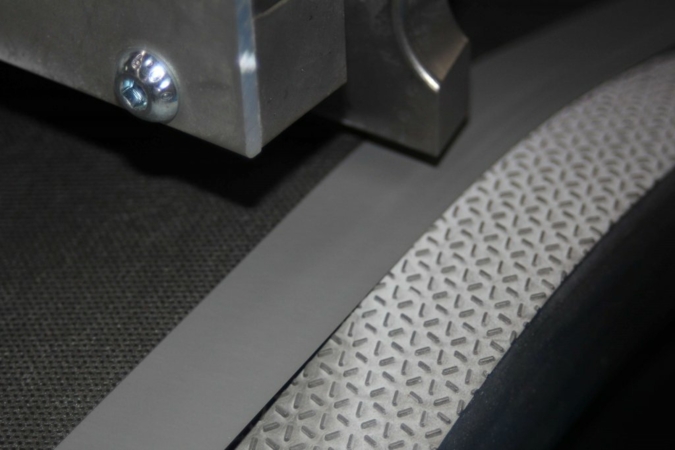

The high productivity and cost efficiency of the process were the key motivation behind the decision to go with ultrasonic welding. All of the company’s products, regardless of their thickness, can be laminated effectively and accurately using the system. © Weber Ultrasonics AG

In the ultrasonic welding plant, two layers of nonwovens and one vaporpermeable film are merged with one another in a continuous lamination process to create roofing underlays. Vadzim Kavaliuk: “We have now been working with the system for more than two years and we are very happy with its performance and quality, as well as the consulting and service provided by Weber Ultrasonics.” © Weber Ultrasonics AG