Search results for "sustainability"

Carrington Textiles and Pincroft as part of their 130 anniversary celebrations have created a distinctive logo to mark the occasion featuring the British Union Jack to represent their proud British legacy. © Carrington Textiles

01/04/2021 – Jubilee

Jubilee

Euratex welcomes the initiative, including the focus on 14 “eco-systems” and the proposal to develop privileged partnerships with trusted partners. © PhotoSG/stock.adobe.com

07/05/2021 – Europa

Europa

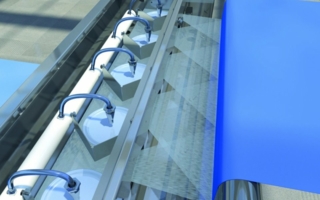

AIE Laundry: This innovative project contributes to a double challenge, transform the country’s textile industry, and support woman in access to a job in equal conditions. This plant guarantees zero discharge and 85 percent water savings, helping to achieve Mission Zero goal: dehydrate and detoxify the denim industry by 2025. © Anish India Exports