Speaking for Domo Chemicals, Alex Segers, CEO called the acquisition "a major step forward". © Domo Chemicals

Speaking for Domo Chemicals, Alex Segers, CEO called the acquisition "a major step forward". © Domo Chemicals

Vertreter aus Wissenschaft und Politik im High Performance Fiber Center, dem modernen Zentrum für Hochleistungsfasern an den DITF. (Vordere Reihe v. re.:) Minister Peter Hauk mit Professor Michael R. Buchmeiser und Peter Steiger (beide Vorstand der DITF) und den Bereichsleitern Dr. Frank Hermanutz und Dr. Erik Frank. © DITF

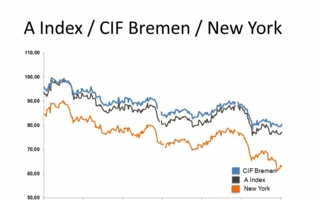

For a year, falling prices have been reflected in the declining values of all the major price indices. © Bremer Baumwollbörse

Helmut Lauterbach, Kelheim Fibres (on the right side), receives the WoW Innovation Award from INDA president Dave Rousse. © INDA

PET bottles are turned into polyethylene fibres whose first textile use is as protective rainwear … after which they are recycled again into T-shirts. © Carl Weiske

In apparel applications, the possibilities of recombinant spider silks are particularly exciting, realizing unprecedented combinations of physical properties such as luxurious feel and breathable comfort with top durability. © 2015 Christopher Payne

Jochen Boos, CEO Indorama Mobility Group: „E-Mobility, autonomes Fahren, Shared Mobility und intelligente Fahrzeuge bergen Chancen für Fasern und Textilien.“ © PHP Fibres