18/07/2024 – Startup Nextevo

Startup Nextevo

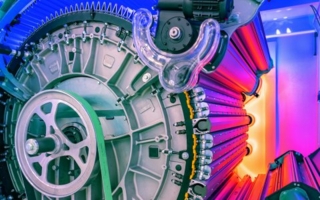

Nextevo, a Singapore-based materials science startup, announced the launch of its inaugural production facility in Dong Nai province, Vietnam. This state-of-the-art ...