Spinning

ITMF (International Textile Manufacturer Federation) has published its International Textile Industry Statistics (ITIS) on productive capacity and raw ...

“Even without large raw material inventory and with basic textile know-how, mills can achieve consistent and reliable laydowns for long-term quality consistency and trouble-free production,” says Stratos Fragkotsinos, Head of Product Management for Mill Management Solutions at Uster Technologies. © Uster Technologies

26/10/2023 – Uster Technologies

Uster Technologies

Raw material management has a high priority for Uster Technologies, based in Uster, Switzerland. That`s clear from “Fiber Q” – part of the new Uster “360 ...

11/05/2023 – Spinning & textile finishing

Spinning & textile finishing

High cost pressure due to dramatically rising energy costs and the steadily increasing importance of in-house environmental and climate protection are ...

The hycuTEC process easily achieves filtration efficiencies in excess of 99.99% in the case of typical filter media. © Oerlikon

06/01/2023 – Sustainable solutions for filtration

Sustainable solutions for filtration

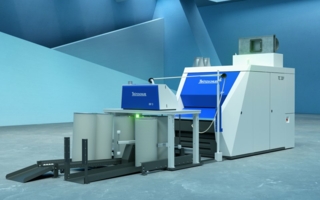

Oerlikon Nonwoven will be showcasing its meltblown and spunbond portfolio at the upcoming Filtech in Cologne, Germany, from February 14 and 16, 2023.

The fibers are pressed through spinning nozzles. The nozzles are located at the upper end of the spinning shaft of the plant. © Fraunhofer ITWM

05/09/2022 – Virtual spinning

Virtual spinning

The Fraunhofer ITWM is developing a simulation software that virtually maps and examines a wide range of spinning processes.