Textile Machinery

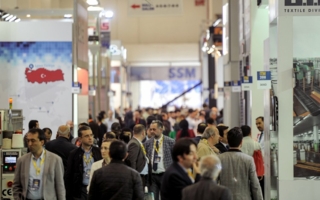

ITM 2021 Exhibition to be held between 22 and 26 June 2021.

Karl Mayer acquired Stoll on 26th February 2020. The merger of the two world market leaders was officially completed with the closing on 1st July 2020. © Stoll

21/08/2020 – After merging with Stoll

After merging with Stoll

Since 12 August 2020: Karl Mayer Stoll Textilmaschinenfabrik GmbH and Karl Mayer Stoll R&D GmbH.

Ralph Greenwood-Mahlo, owner: “My grandparents laid the foundation for Mahlo’s success. Our task now is to lead the company into an equally successful future without forgetting our core values. Mahlo is a family business that takes responsibility for its employees and values fair and respectful treatment of customers and business partners.” © Mahlo

06/08/2020 – 75th anniversary

75th anniversary

If Dr. Heinz Mahlo could see what has become of his company, which he founded in 1945 after the end of World War II – he would certainly be very proud.

Maske mit Sichtfenster von Nadine Beninga unterstützt Gehörlose oder Schwerhörige dabei auch weiterhin Mitten in der Gesellschaft zu bleiben. © Beninga

25/05/2020 – In eigener Sache

In eigener Sache

Hier stellen wir die Top-Artikel aus unseren Rubriken vor. Der meistgelesene Beitrag in der KW 21 kommt aus der Rubrik „Fashion“.