Textile Machinery

Endprodukt der Vorspinnmaschine: Die so genannte Flyerlunte auf Spulen aufgewickelt. Dank der Dynamischen Energieversorgung DEV von Koch funktioniert der Prozess auch bei instabiler Stromversorgung ohne Garnrisse. © Michael Koch GmbH

09/12/2019 – In eigener Sache

In eigener Sache

The company currently employs 220 Jeanologist from 24 nationalities and has clients in five continents through its ten subsidiaries. © Jeanologia

04/12/2019 – Sourcing model of the future

Sourcing model of the future

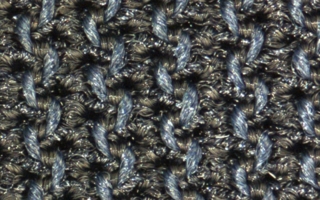

End product of the roving frame: the so-called rovings wound up on spools. Thanks to the DEV Dynamic Energy Supply from Koch, the process runs without yarn breakage even with an unstable power supply. © Michael Koch GmbH

03/12/2019 – Dynamic Energy Supply (DEV) protects yarns in case of power failure

Dynamic Energy Supply (DEV) protects yarns in case of power failure

In the spinning mill, the yarns made from raw fibres are first wound onto large reels and then unwound and rewound for practically every subsequent process. © sandsun/iStockphoto