28/08/2017 – TITV Greiz — auf Deutsch lesen

A thread for minimalconducting track distances

Several developments regarding embroidered electronics such as embroidered circuits have been realised at TITV Greiz in the past years.

Elitex is a conductive and textile processible polyamide thread with a coating of pure silver. Special requirements of conducting of electronic components had to be considered during optimisation. Conducting track distances of 1.27 mm are available with Elitex after electrochemical modifications of metallised thread materials as well as investigations of the embroidery fabric.

Relating to the continuous miniaturisation of electronic components, the research project “Development of an embroidery thread for the realisation of textile circuits with minimal conducting track distances to equip electronic components - µStick” was initiated to adapt the conductive thread for the realisation of embroidered cir-cuits with minimal track distances on textile substrates.

The challenge while generating minimal track distances is the risk of short circuits caused by off-standing filaments of nearby tracks.

A new conductive thread with less off-standing filaments and smaller diameter as well as with sufficient conductivity would be necessary for the prospective embroidery-technical implementation of track distances about 0.65 mm for smd components with the same pin distance.

New thread constructions of metallised polyamide yarns and different types of finishing have been studied in the project and tested for their suitability. The results show, that Shieldex yarns with 33 dtex f12 are suitable basic yarns.

To adjust a defined conductivity, electroplating of pre-metallised thread materials is necessary.

The development result of a fine conductive embroidery thread is a one-level ply yarn construction with the specification Elitex dtex f12 x 2. The electroplating follows the twisting process. The average measured thread resistance is 48 Ohm/m over a thread length of 100 m. The thread diameter below 300 µm meets the requirements.

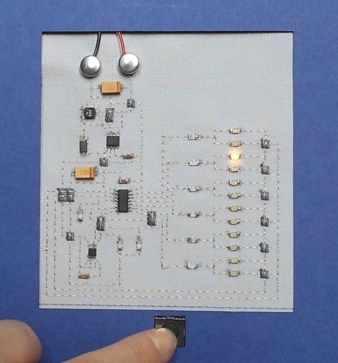

The Contacting of the components with embroidered conductor paths was realized by hand-soldering. The embroidery thread withstands temperatures up to 220 °C. The use of lead-free solder pastes was carried out because of the current legislation.

After evaluating and optimizing all necessary parameters, the embroidery technology of selected layouts was carried out. The reproducibility and reliability of the embroidered conductor paths and circuits were investigated on these samples.

A demonstrator shows the functionality of an embroidered circuit with minimal con-ducting track distances with the µStick threads and the mounting of smd components.

The project shows how existing systems or technologies (conductive thread, embroidery fabric, mounting, contacting and embroidered circuits) are able to follow today’s requirements of the miniaturisation by means of adjustment of the conductive thread material. Therefore flexible textiles can be used as an alternative to rigid printed circuit boards. Main fields of application of the embroidered circuit are the usage in the electronic equipment, medical technology and automotive sector.

Acknowledgement

We would like to thank the federal ministry for economy and energy for its financial support of the research project MF 120200, which were funds from the federal budget.