30/03/2021 – High-performance textiles, compression and sportswear — auf Deutsch lesen

Fraunhofer ITWM: Realistic simulation of technical textiles

New software program TexMath enables simulation and optimization of textile products. An article by Annika Dreßler, Fraunhofer ITWM.

Accelerated development and optimized design of technical textiles while reducing experiments? The demand for techniques that can realize this is especially high in areas such as the sports, medical, and clothing industries. The Technical Textiles team of the Flow and Material Simulation department at Fraunhofer ITWM has taken up this challenge and is developing simulation methods that allow efficient prediction of textile behavior under stretching, shear, bending, torsion, or compression. It is also possible to simulate wrinkling under stretching as well as shrinkage of yarns or critical shear angles throughout the manufacturing process.

From high-performance textiles to compression and sportswear: The modular software program “TexMath” of the Fraunhofer Institute for Industrial Mathematics ITWM enables both the simulation of mechanical material properties and the optimization of textile products.

The TexMath simulation software they developed ensures that process chains in production can be adapted to new materials in advance. Complicated patterns and layers can be mapped with the help of the software and a direct connection to the textile machine can be made. Desired woven, knitted and warp-knitted products are accurately simulated with the software and their material properties computed. In addition to evaluating a particular textile design using simulation, the tools also provide optimization of performance characteristics for different design variations. The goal of the software, according to team leader Dr. Julia Orlik, is to “realize the design according to product properties and target criteria”.

Optimal compression

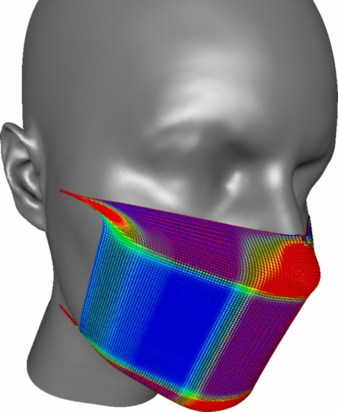

One area of application for the TexMath software is the optimization of compression textiles for the medical sector or for sports. For optimal effectiveness, the fit of the material is particularly important. For example, the knitting process can be simulated with TexMath to create a bandage with predefined compression properties and thus design the optimal knitted fabric. This virtual bandage is then loaded in another simulation and put on a virtual arm or leg. Thanks to TexMath, the calculated pressure profile makes it possible to evaluate the compression properties of the bandage in advance and also to directly control the knitting machine according to the optimal design.

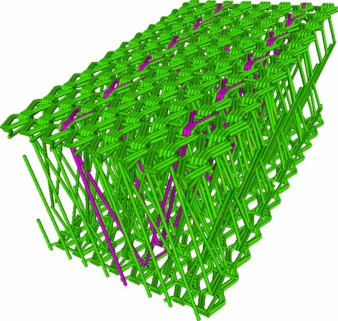

“TexMath can also be used to design spacer textiles, such as those used for the upper material of sports shoes and for the production of high-performance textiles, and to optimize them in advance in terms of structure and fluid mechanics,” say Dr. Julia Orlik and department head Dr. Konrad Steiner, naming further areas of application for the software.

A demo version of the software program will soon be available. The newly developed input interface is particularly user-friendly. The textile class (i.e. knitted, warp-knitted, woven and spacer fabrics) can be easily set. The new graphic interface allows simple and fast configuration.

A real all-rounder

TexMath consists of several components: MeshUp, FibreFEM and FIFST. Each of the components included in TexMath has its specific field of application. In addition, the tools have interfaces to each other as well as connections to the software GeoDict of the Fraunhofer spin-off Math2Market, which can be used, for example, to perform fluid mechanical simulations on the textiles.

Starting in April, we will report in more detail on this interesting research project in several parts! It’s worth following along.