20/02/2018 – Microfactory - part 3 — auf Deutsch lesen

The work steps in the Microfactory - Step 2: Printing

The customer has created his desired design – now it’s getting serious, because it’s time for production to start!

The special feature of the Microfactory concept? All the work steps are realized on just a few square meters, so the customer can see it all happening live while his product is created.

The technical advances in printing were a starting point for the birth and development of the Microfactory. Digital printing today makes it possible to produce printed clothing in small quantities – quickly and inexpensively. Several companies work hand-in-hand to carry out printing in the Microfactory, and each company uses its own expertise to produce the best possible printing results.

Companies work hand-in-hand

The RIP-Software of the ErgoSoft company, for example, ensures the color-consistent processing of the design data. “In apparel production, it’s particularly important to secure the transformation of design colors into the printer’s output color space – then a product will come out of the printer just like the designer, in our case the customer, imagined it would be,” says Samuel Labhart of Ergosoft. The solution here is the interface between the digital preparation and the actual printing of the garment – this is where the product can be viewed one last time before it’s finally produced, and production can be stopped here if necessary. ErgoSoft RIP offers a complete color management system, an integrated linearization and profiling solution, and color optimization tools designed specifically for the textile market. The can:scan and can:view systems of the Caddon company simultaneously ensure realtime, visual and metrological color control at all the locations involved. The can:scan system provides the color-consistent digitization of complex & structured patterns and designs, as well as the most efficient and fastest way of precisely profiling a color-consistent printing process.

“Realize now” - Munich Fabric Start 2017

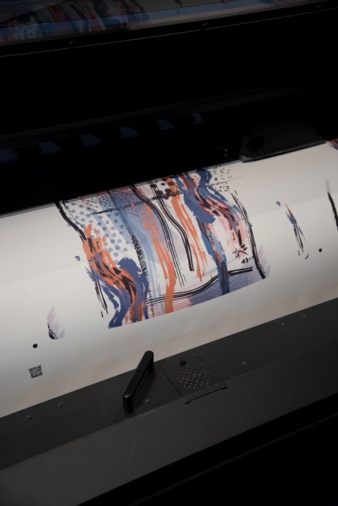

In the Microfactory, which was realized under the motto “Realize now” for the Munich Fabric Start 2017, individual designs were printed on transfer paper of the Coldenhove company using a Mimaki sublimation printer. “The color is directly applied to the selected fabric in the marker of a shirt or a vest, for instance. The next step is calendering, after which the color is heat-set on the material. Then the product is ready for cutting”, explains Mimaki’s Nathali Stumpf. Thermal transfer on to ‘Heatjet’ calenders ensures a brilliant print image.

The Multi-Plot company, a system partner, offers turnkey solutions for the entire process step.