04/03/2021 – Knits finer than E32 — auf Deutsch lesen

VDMA Webtalk: The fine gauge rule

Representatives from Mayer & Cie., Groz-Beckert and Thies talked about Dos and Don’ts for circular knitted fabrics finer than E32.

by Claudia Bitzer

At a VDMA Webtalk on February 17th 2021, representatives from Mayer & Cie., Groz-Beckert and Thies talked about meeting challenges of fine gauge circular knitting. In line with the increasing popularity of fine gauge fabrics, around 300 participants from all over the world followed the online event by the German association’s textile machinery branch.

Knits finer than E32 consist of extremely small loops leading to light, opaque and functional fabrics, which have become increasingly popular and are used for various applications. Thanks to their delicate touch, they are common in high-quality underwear and basic layer garments.

In active wear and athletic wear, fine gauge fabrics are a distinguishing feature, same as in swimwear. For fine gauge circular knits there are also technical application, e.g. in filters.

Meeting the fine gauge challenge: “Much more than a few extra needles”

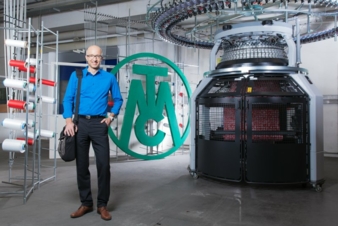

Circular knitting machine builder Mayer & Cie. started the presentations at the VDMA Webtalk. Wolfgang Müller, Head of Sales and Service, talked about producing knits with gauges from E32 to E44 – or even up to E60, to which he referred as ultra fine gauge. Fabrics so delicate come to use in nightwear, for instance, and are considered a niche market.

When it comes to producing fine fabrics as thin as paper, Müller stated that “it takes much more than a few more needles” for a high quality result.

During the knitting process, the major challenges are omitting vertical and horizontal lines as well as barré effects.

High quality knitting elements such as needles, sinkers, cylinder, dial and sinker ring are key especially when it comes to omitting vertical lines.

Keeping a constant yarn tension from bobbin to feeder will counter the majority of horizontal lines.

A non-concentric or non- horizontal knitting head can lead to barré effects; these can be countered by high precision in the knitting equipment, particularly the knitting head. This becomes even more important in knitting fine gauge interlock, when cylinder and dial have both to be concentric, perfectly levelled and at a constant distance to each other.

Consequently, Mayer & Cie. introduced a “fine gauge rule”, which reads as follows: Premium yarn + premium machinery + in-depth process know how = Premium fabric quality

Fine gauge challenge in the needle department: precision as a prerequisite

Roland Simmendinger from Groz-Beckert also stressed the promising perspectives of fine gauge circular knitting in single jersey, rib and interlock. When explaining the correlation between finer gauges and higher number of needles, he drew attention to the fact that a common fine gauge needle measures only 0.26 mm. So obviously, a high level of precision is needed to achieve the desired result. The same is true in sewing, so Simmendinger concluded:

“In each step of the value chain, requirements upon fine gauge knits are high. Only a holistic view on the fine gauge value chain will make us achieve the target.”

The finer gauge challenge in dyeing: adequate treatment for high quality results

When looking into the dyeing process, Ralf Stange from Thies once more affirmed the need for precision in all steps of the process. To receive a premium product from this process, a high quality pre-product is a pre-requisite. In the dyeing process, working with the right nozzles is an important aspect. As the fabric is very lightweight, Thies pays attention on putting low tension on the fabric when pulling it into and out of the fabric chamber in two ropes. An adjustable fabric chamber is a further component in an optimal dyeing set-up for fine gauge knits. Thies also pointed out the importance of efficiency and ecological aspects.

Ralf Stange: “Coming back to the fine gauge rule, we can conclude it is important to consult the experts for a first quality result.”

Conclusion:

Circular knitwear in fine gauge is used for sportswear, home wear and in the lingerie sector. At least as high as the trend factor is the demand in production: For a high-quality end product with an extra-fine feel, an optimum combination of yarns, needles and circular knitting machines is required. A high-quality knitted fabric of this fine quality can only be achieved with a combination of premium yarn, premium machine and a high level of process expertise. The result, however, is convincing: a very thin, soft knitted fabric that is not bulky and has a wonderful feel. No wonder, then, that more and more consumers are becoming enthusiastic about Fine-Gauge garments. The speakers agreed: If customers are to come back, it is advisable to focus on high quality in production!