25/03/2024

At this point, we present the five most read articles of the past week. The ranking is based on your click behavior on the website.

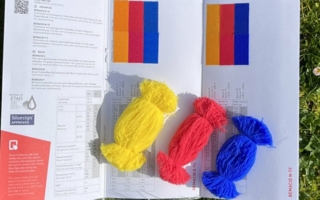

“BeSo Responsible” by CHT mixed with Fulgar´s “Q-Cycle“ equals a sustainable dyed yarn. © CHT/Fulgar

Sulfur dyeing technology become a staple in the production of denim, casual wear and workwear fabrics over the past 100 years, with excellent color fastness and cost-efficiency. © Archroma

Sulfur dyeing technology become a staple in the production of denim, casual wear and workwear fabrics over the past 100 years, with excellent color fastness and cost-efficiency. © Archroma

Artistic Milliners and Archroma leverage eco-advanced sulfur black dyestuff to rewrite the future of denim. © Artistic Milliners