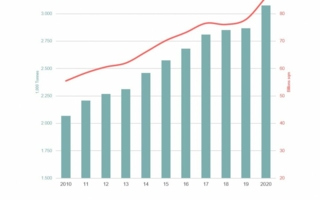

According to figures collected and compiled by the Edana secretariat, production of nonwovens in Greater Europe grew by 7.2 percent in 2020 to reach 3,075,615 tonnes (and 85.9 billion square metres) with a total estimated turnover of 9,555 million euro. The total output of the 27 European Union countries is now over 2.15 million tonnes. © Edana